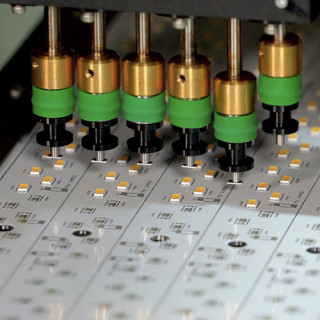

The HD806 and HD812 models were developed for fast and highly accurate mounting of LEDs in large batch sizes. These models are connected to an optical centering system, which allows image processing for scanning through a stationary camera.

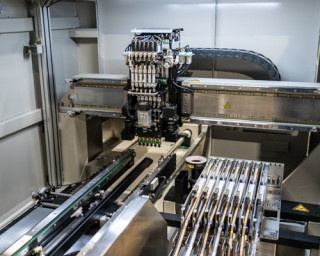

The new HD806 / HD812 6-head high-speed linear drive portal allows simultaneous detection of up to 30,000 LEDs per hour (per IPC-9850 standard). Alignment t “rue Fly Over” with the camera facing upwards between the feeder base and the PCB, aligns the components while the head is in motion. Thanks to the supplied software, the feeder positions are optimized prior to placement to minimize head trace and tool change.

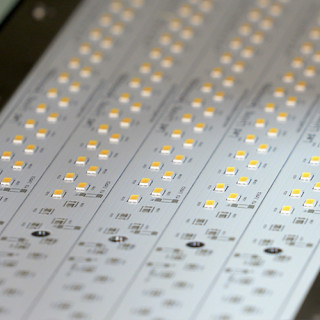

Flexible circuit strips, round LED bulb boards and irregularly shaped boards can be installed quickly, accurately and reliably on all HD series models. For long LED tubes, the HD812 model offers a maximum board size of 1200 mm. (The HD806 model offers a maximum board size of 600 mm. On all models, plates are fabricated in a single pass for maximum efficiency and throughput. The HD806 / HD812 comes standard with a worktable and magnetic stand or can be configured for line automation with a SMEMA-compatible in-line coveyor. .

.

The HD806 / HD812 offers uninterrupted production. The ability to automatically switch to another feeder when an operating feeder runs out of components allows the operator to refill and replace the empty feeder without even stopping production. The HD806 / HD812 can accommodate up to 16 roll feeders. These special servo feeders use brushless motors for longer feeder life in all-day production conditions. With these feeders, it is also possible to split a new roll into an old roll to minimize production interruptions

.

Unlike standard automatic placement machines, which have been adapted to LED assembly, the HD806 / HD812 is specially designed for this purpose, so that it can assemble LED boards really well.

The HD806 / HD812 places LED components from 0402 to 20mm x 18mm, including standard and irregularly shaped LEDs for connections or small resistors. Each of the HD806 / HD812’s six heads has positive air pressure to blow out “sticky” LED components. Non-stick Teflon® coated nozzles are also available, including custom nozzles. Curved LEDs can be securely positioned using special nozzles that are designed not to contact the optical lens during pick-up and placement, thus protecting overall light output and component reliability.

© All rights reserved AB Electronic Devices | Legal notice | Privacy policy | Cookie Policy | Shipping and returns policy | Contact