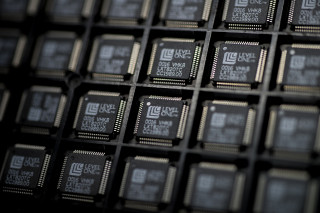

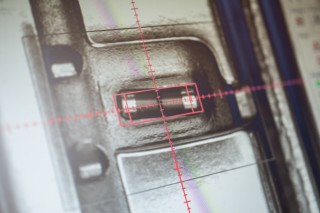

The BA392P1-V and BA392P2-V Pick and Place models were specially developed for fast and high precision assembly of small and medium batches. These models are equipped with an optical alignment system that allows image processing directly in the “Vision on the Fly” placement head. Ensuring optimal measurement of SMD components such as 0201, SOIC, PLCC, BGA, uBGA, CSP and QFP, as well as irregularly shaped components down to a 0.3 mm grid.

Usinga sophisticated camera and prism mechanism, components up to 16×14 mm are measured directly in the head. This eliminates the trip to the stationary camera.

nComponents larger than 16×14 mm are measured with an optional “bottom view” camera. Components up to 150×100 mm are accepted

.

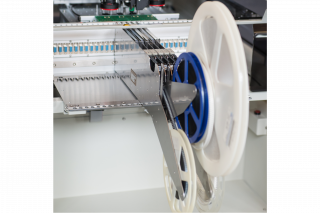

Theremoval area can be equipped with any number of different feeders. From automatic belt feeders to IC trays.

Differentmethods are available for programming. Tailored to your needs, using Teach-In or CAD conversion. Of course, a barcode system can also be used

.

© All rights reserved AB Electronic Devices | Legal notice | Privacy policy | Cookie Policy | Shipping and returns policy | Contact