BT301 Benchtop Remelting Furnace

Dynamic thermal profiling using a remelting furnace by an Android™ Operating System. Match your thermal process specifications of preheating, soaking, remelting, cooling on the first PCB to be produced with the revolutionary new BT301 batch use remelting furnace.

Having the thermal conditions of an in-line remelting system in a benchtop unit with a complete dynamic thermal process. The BT301 furnace is ideal for product development, prototyping and small production runs. Soldering profiles are easy to configure and control through the unique BT301 hardware control app with Android operating system. The dynamic control system takes care of the size and complexity of the assembly by making it a closed-loop process, something only large and expensive thermal systems can offer.

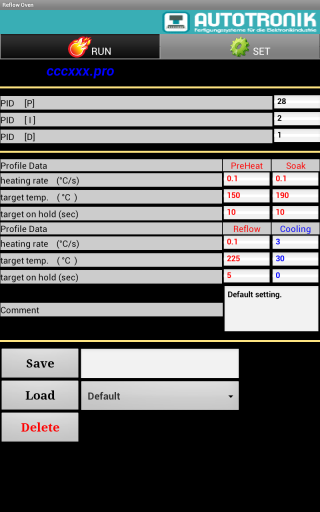

The BT301P is ideal for product development, prototyping and small batch production. With the Android-based control application, it is easy to create and save weld profiles. The dynamic control system monitors the size and complexity of the circuit and converts it to an overall process.

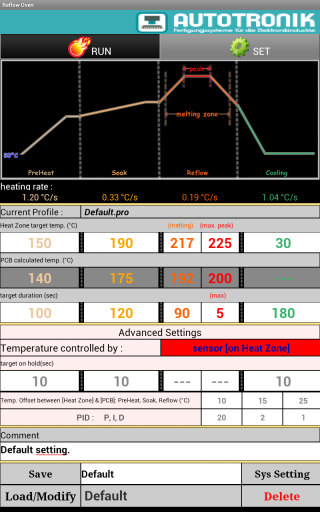

The BT301P has a modern user interface where it can work dynamically and in real time. The device can graphically display real-time feedback from sensors connected directly to the circuit board and/or pass it to external sources such as a PC or printer.

The real-time temperature profile is created from the oven or through the PCB temperature and displayed during the process cycle. The actual values are easy to compare with the set values, allowing precise parameter settings.

Process data can be saved via WiFi connection and used for training, development and quality control purposes.

Features:

© All rights reserved AB Electronic Devices | Legal notice | Privacy policy | Cookie Policy | Shipping and returns policy | Contact